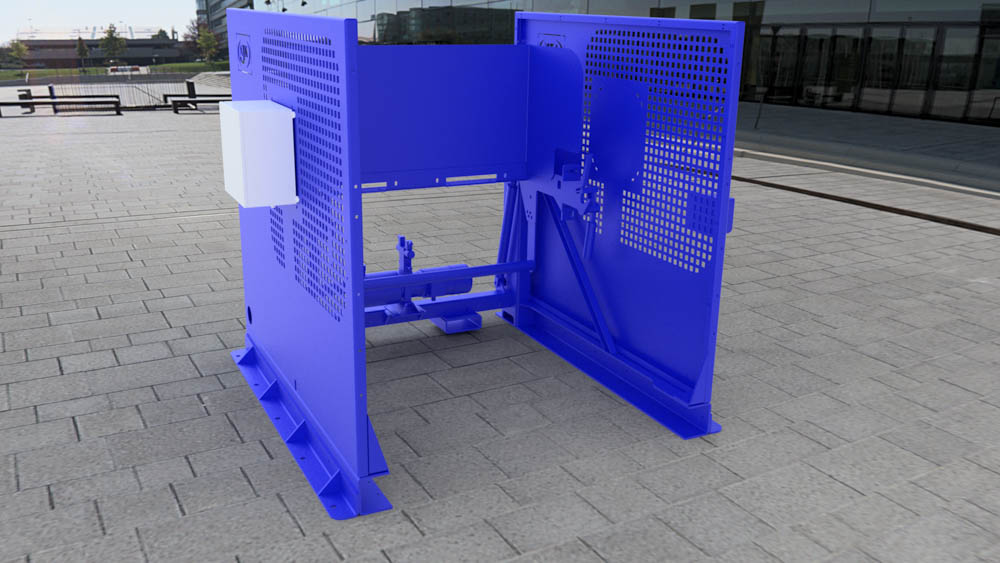

Lifting tilt installations

A tilter is a tool that is used to dispose of waste in a portable or static compactor in a safe way. The electric-hydraulic driven lifting tilt installation facilitates the emptying of roller containers, mesh stillages, pallet-boxes and DIN containers significantly.

We offer driveable and static tilters with various lifting possibilities, geared to your needs.

Do you want to know more? Please contact one of our experts.

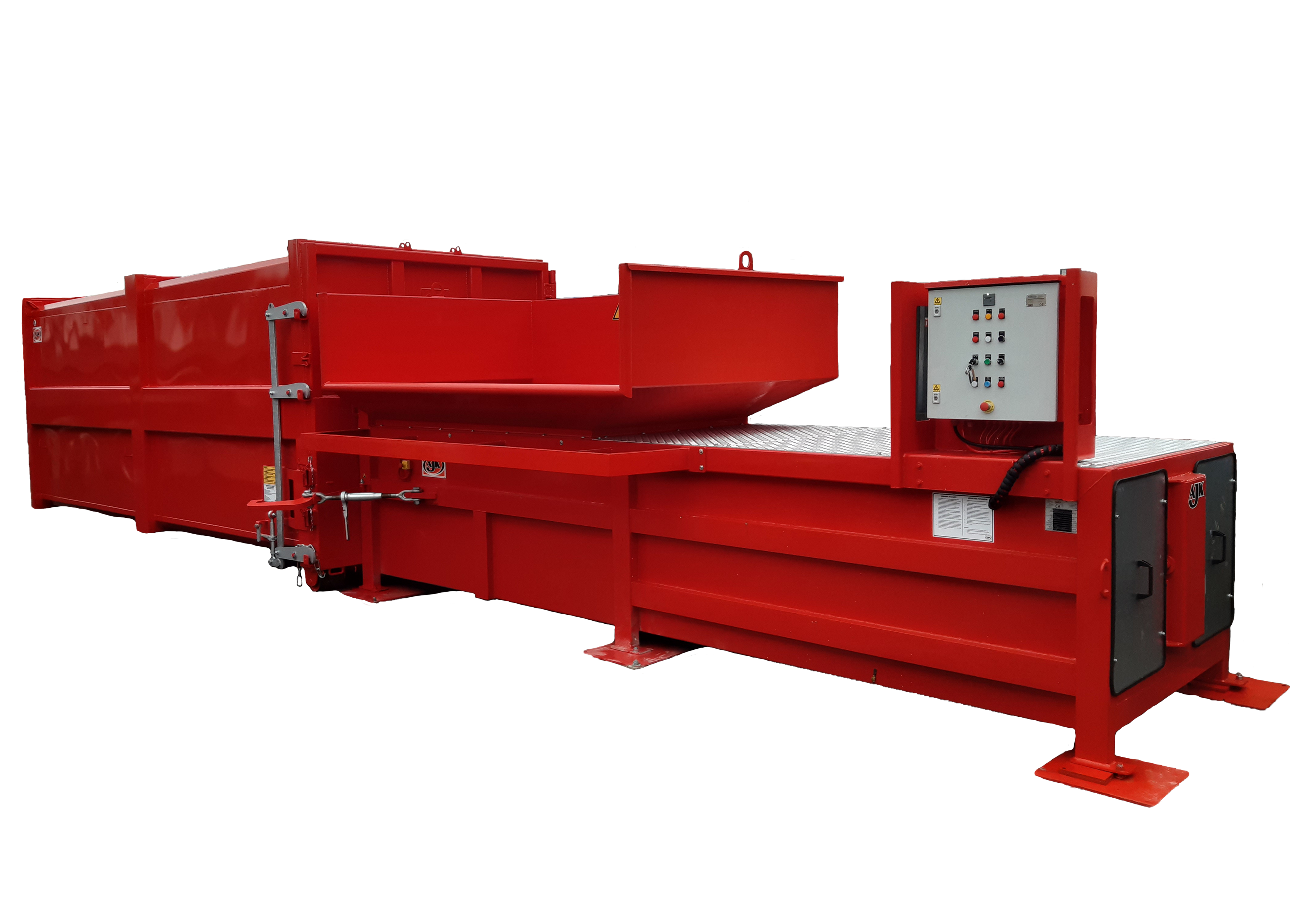

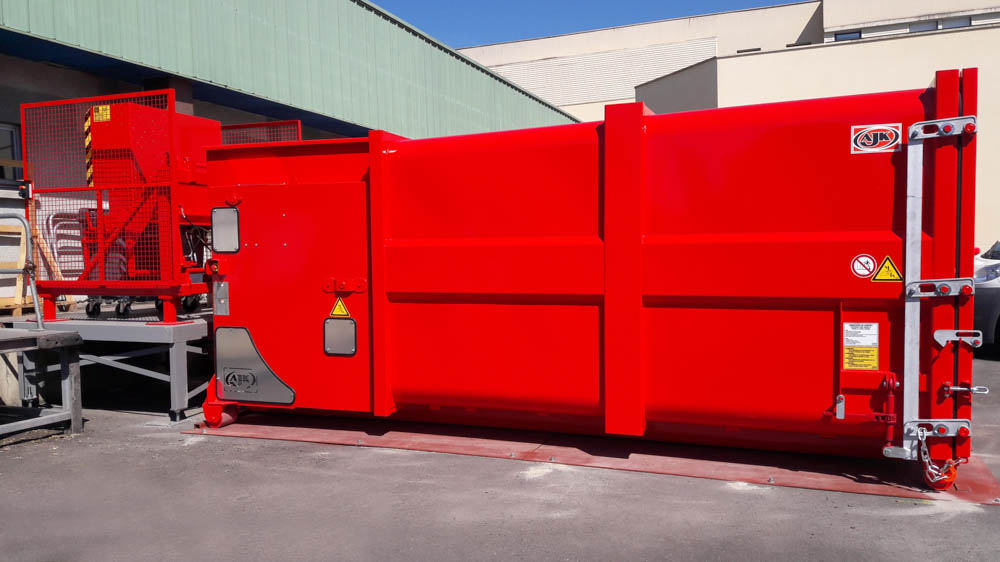

The added value of our waste compactors

Waste compactors are used to store more material in less space, which is why they are called waste compactor machines. A lot of waste types can be compressed. Waste compactors for paper or cardboard, but especially for plastic and residual waste, can lift your waste management to a higher level. Waste compactors are perfect for liquid waste.

Which kinds of waste can not be compressed? Waste compactors are not suitable for e.g. wood and metal waste.

Experience has shown that the payback period of a waste compactor is only three to four years. Maybe you are convinced now. But why choose an AJK waste compactor?

- At AJK, you buy directly from the producer. No intermediaries that make things more complicated. You tell us what you would like to use the waste compactor for and how you are going to fill it. As soon as we have this information, we will make you a custom offer. We will pay regular visits on-site in order to see how things are going and to make adjustments when necessary.

- Our sixty years of experience is reflected in an optimized product that can reach an ideal filling degree. Solid, but light waste compactors. Fastenings that close easily. A high-end paint finish.

- A service team that is accessible 24/7 and that will provide on-site service within 2 working days.

Save money on transport

If you have to plan a waste transport only once a week instead of once a day, you save on costs and hassle. And it is more durable.

Safeguard continuity

With a portable compactor you are not affected by standstills, production can continue at all times.

Ensure hygiene and safety

When you work with e.g. food products, it is very important to store your waste in a closed space.

Remote Access

By means of a computer inside the compactor we will both be able to follow-up on the status of a malfunction at any time. This enables remote servicing and the compactor is optimized through the connection with the internet of Things.

AJK Remote Access

Engineering sustainable smart technology for a greener world and a lower footprint.

With the AJK remote access, AJK has long been strong in the market of smart technology and remote information gathering.

The Remote Access Ready makes it possible to communicate with the press. On the Cloud Platform, all data related to the press is collected. At the same time, the customer can save individual settings online for each press and its location.

With the AJK Remote Access, the fleet management of the press can be optimized. The customer can predict filling patterns and analyze operating hours based on the collected data. This will significantly reduce waste management costs.

Not only will you be able to eliminate unnecessary truck trips, but customers who join AJK in the Remote Access story also contribute prominently to CO2 reduction. Because also at AJK, the key words environmentally conscious and sustainability are of paramount importance.

Custom

At AJK we have our own flexible production site, which means you can come to us for various custom projects.

Service

At AJK we value quality, even after purchase. This allows us to extend the life of your product.

Renting

With AJK Renting we offer a quick solution for customers who do not yet want to make a purchase or for whom it is not necessary.

Production

From our experience, we are aware that our products for customers often have to meet a number of standard requirements.